Whether you're developing a new material or conducting quality inspections on batch products, a stable and precise Electronic universal testing machine is an essential tool for engineers across industries.

As performance requirements for materials continue to rise, how can you perform mechanical property tests quickly, reliably, and accurately? The answer lies in choosing a versatile, easy-to-operate, and high-precision electronic universal testing machine—a solution designed to meet real testing challenges.

Facing These Testing Challenges?

Need to test tensile strength or compression properties, but your equipment can’t handle multiple test types?

Concerned about force measurement inaccuracies that could affect product pass/fail decisions?

Want a user-friendly system with intelligent software and auto-reporting, but struggle with complex interfaces?

The electronic universal testing machine is engineered to solve these problems.

One Machine, Multiple Functions — All-in-One Testing Capabilities

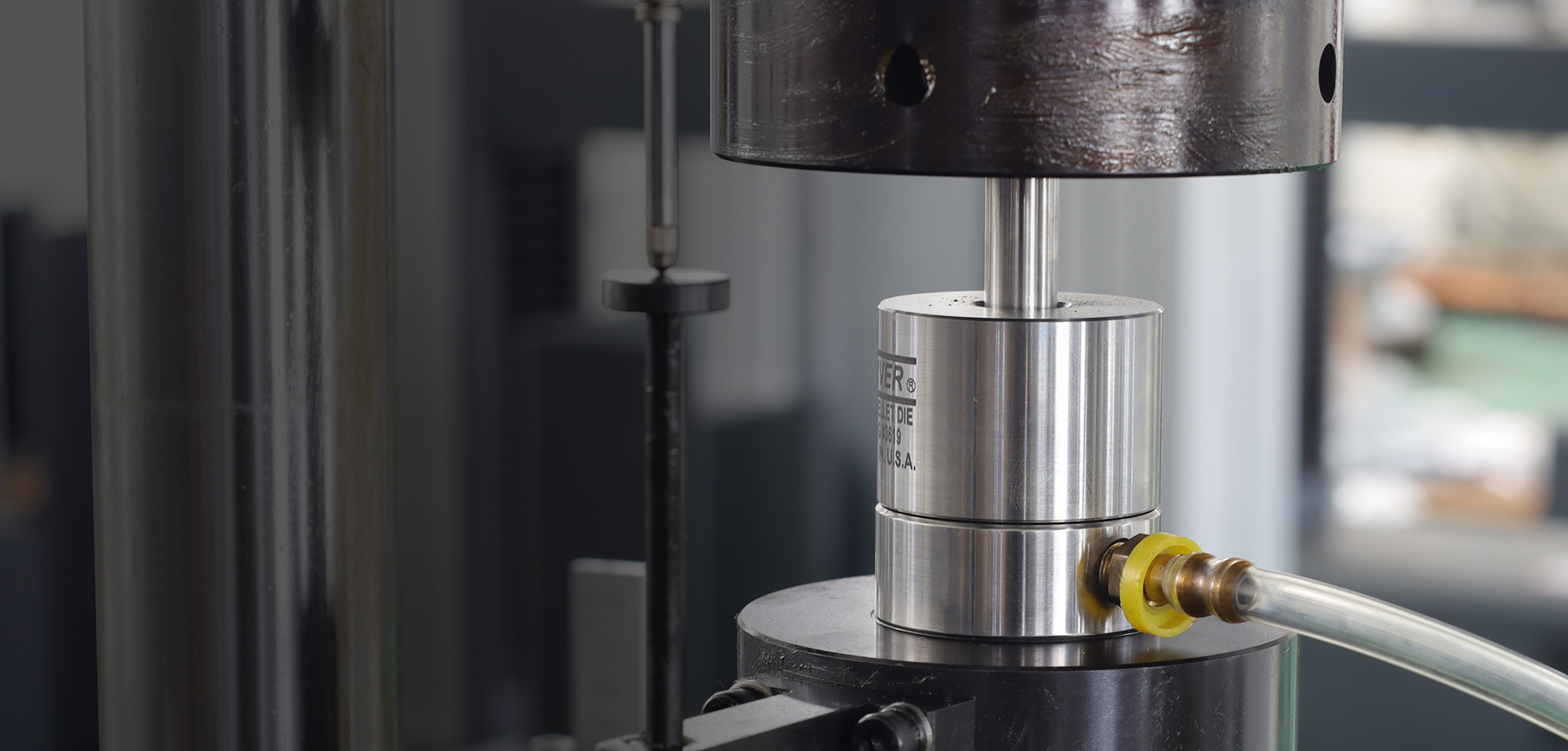

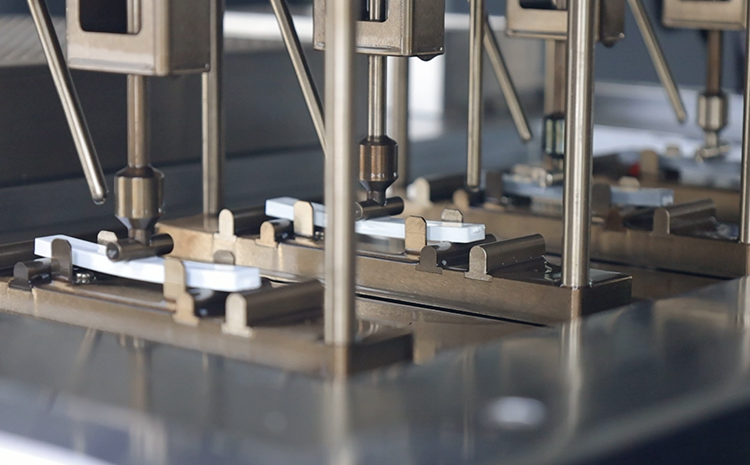

The electronic universal testing machine combines tensile, compression, bending, peeling, and shearing functions into one high-performance device. Its core advantage lies in its high-precision servo control system and modular fixture design for quick adaptation.

Common test types include:

Tensile and yield strength of metal materials

Breaking strength and elongation of rubber, plastics, and films

Three-point bending of composite materials

180°/90° peel strength of adhesives and coatings

Insertion force, pull-off force, and compression strength of components

Key Technical Specifications (Standard Model)

Maximum Test Force:5kN / 10kN / 20kN / 50kN (customizable)

Load Accuracy:Grade 0.5 (±0.5% or better)

Displacement Resolution:0.001 mm

Test Speed Range:0.01 mm/min ~ 500 mm/min

Effective Test Stroke:600 mm ~ 1000 mm (extendable)

Control System:Servo motor + PC interface + real-time graphing

Data Output & Reporting:Auto-generated Excel/PDF reports with charts and annotations

Standards Compliance:GB, ISO, ASTM, DIN, and more

Widely Used Across Multiple Industries

Metallurgy & Steel: Evaluate tensile and compressive performance of steels, copper, aluminum alloys

Plastics & Rubber: Measure tensile break strength, peel force, and elongation

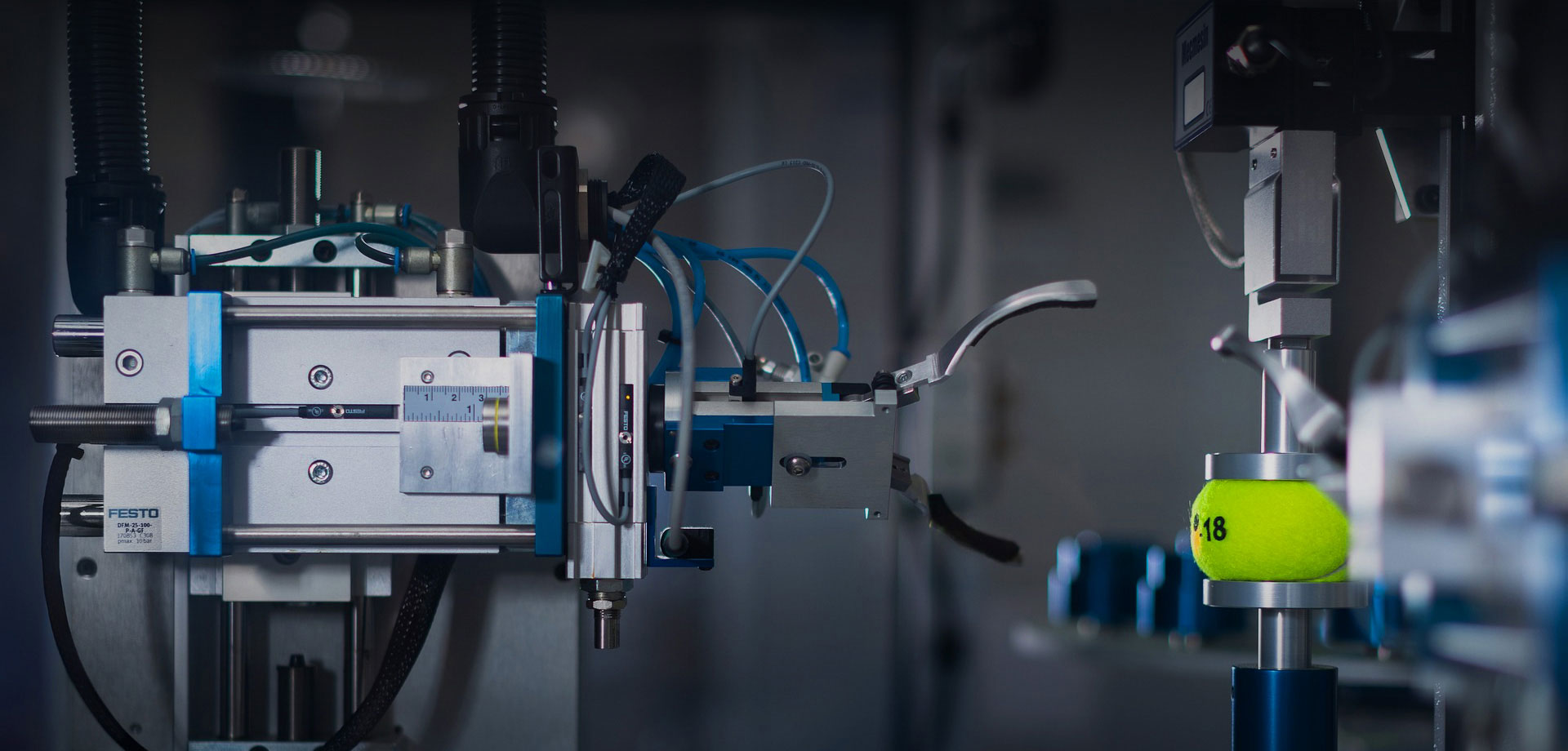

Electronics & Connectors: Test insertion/pull-out force, bonding strength, and structural integrity

Packaging Industry: Analyze adhesion, seal strength, and material durability

Research & Education: Conduct lab experiments and mechanical analysis for material R&D

Why Choose Our Electronic Universal Testing Machine?

High precision and stable data

Intuitive software with automatic report generation

Modular fixture system for quick test changeovers

Customizable for industry-specific standards

Remote installation and responsive after-sales support

Conclusion: One Machine to Cover More Testing Needs

In material performance testing, precision equals product confidence. The Electronic universal testing machine, with its reliable data, versatile testing modes, and operator-friendly interface, is quickly becoming the go-to solution for enterprises and laboratories.

If you’re looking for a reliable, multifunctional, and customizable testing solution, contact us today for expert consultation and product recommendations. Make your material testing smarter and more efficient—starting now!