Electronic Universal Tensile Testing Machine: Testing Capabilities and Application Overview

I. Equipment Functional Positioning

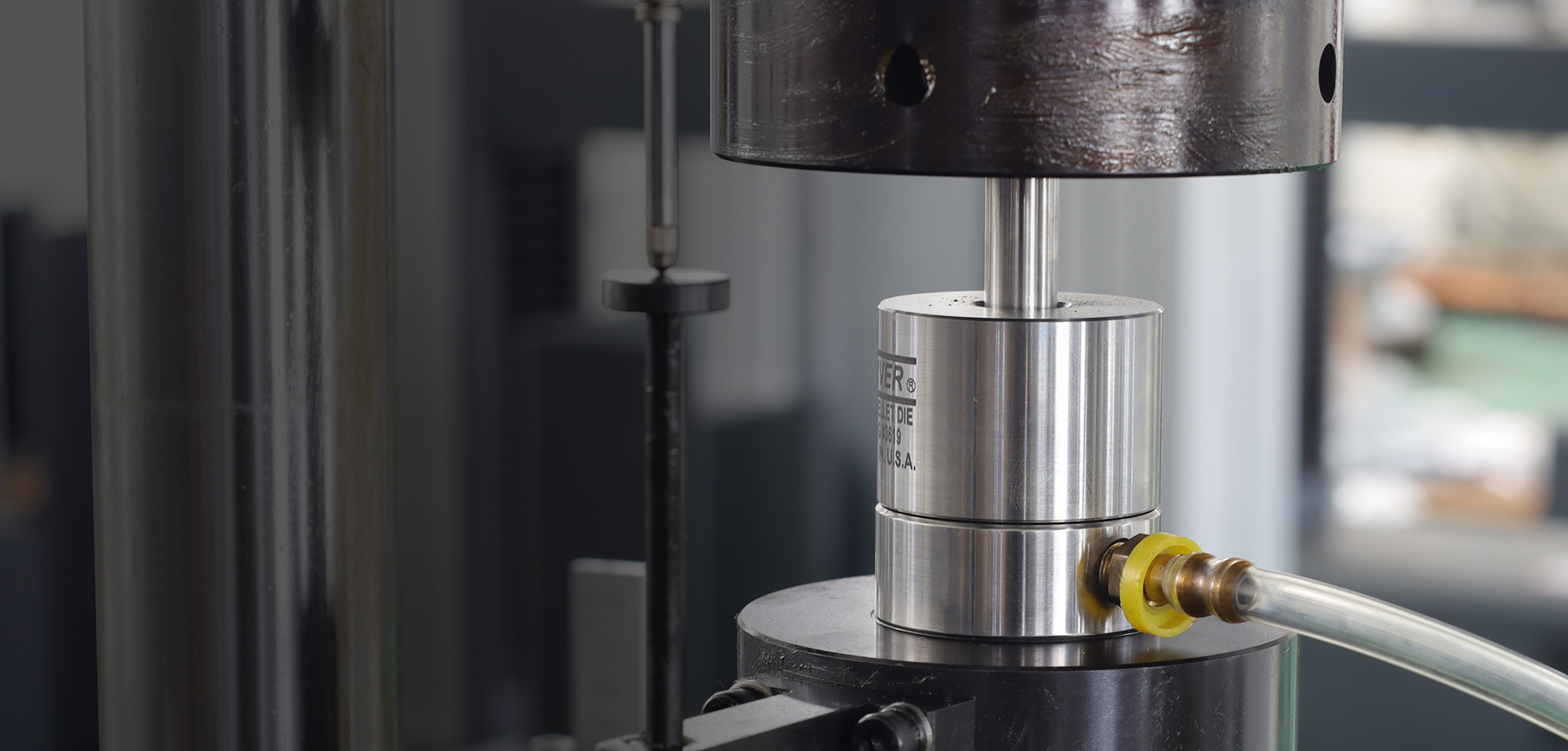

The electronic universal tensile testing machine serves as core equipment in modern materials laboratories. Through a high-precision servo control system (with a resolution of up to 0.01μm) and a modular fixture design, it achieves comprehensive characterization of the mechanical behavior of materials. Its testing capabilities cover over 90% of static mechanical performance testing needs (according to ISO 6892-1:2019 statistics).

II. Core Testing Performance Matrix

Basic Mechanical Performance Testing

Tensile Testing: It can accurately capture the entire process of a material from elastic deformation to necking and fracture, particularly suitable for:

Metallic Materials: Yield strength (Rp0.2), uniform elongation (Agt)

Polymer Materials: Nominal fracture strain (εb)

(Test Case: Tensile strength test of automotive-grade 6061 aluminum alloy at a speed of 2mm/min)

Special Condition Simulation Capabilities

Test Types and Industrial Applications:

Compression-Bending Composite: Earthquake resistance performance evaluation of construction steel bars, requiring a three-point bending fixture and anti-tipping device

High-Temperature Peel Test: Adhesion force testing of new energy battery electrode tabs, requiring integration with a constant temperature chamber (up to 400°C)

III. Cross-Industry Application Cases

Aerospace Field

Using ASTM D3039 standards to test the interlaminar shear strength of carbon fiber composite materials, with a load control accuracy of ≤±0.5%FS required.

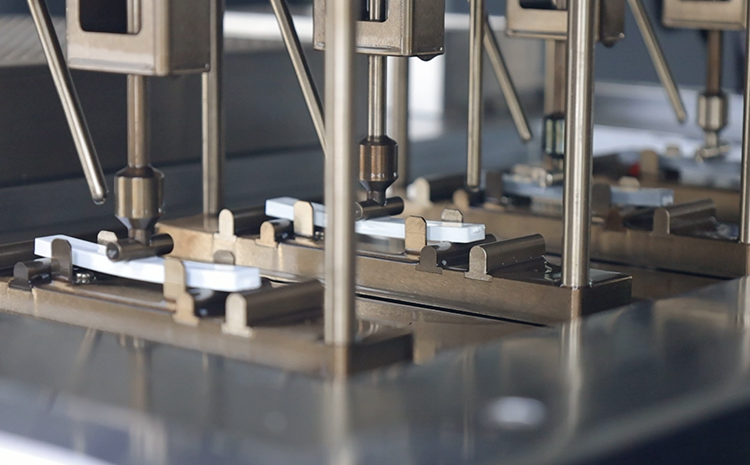

Medical Equipment Verification

Determining the breaking strength of medical sutures according to YY/T 0681.1, requiring the use of a 0.5N range micro fixture.

IV. Technological Development Frontier

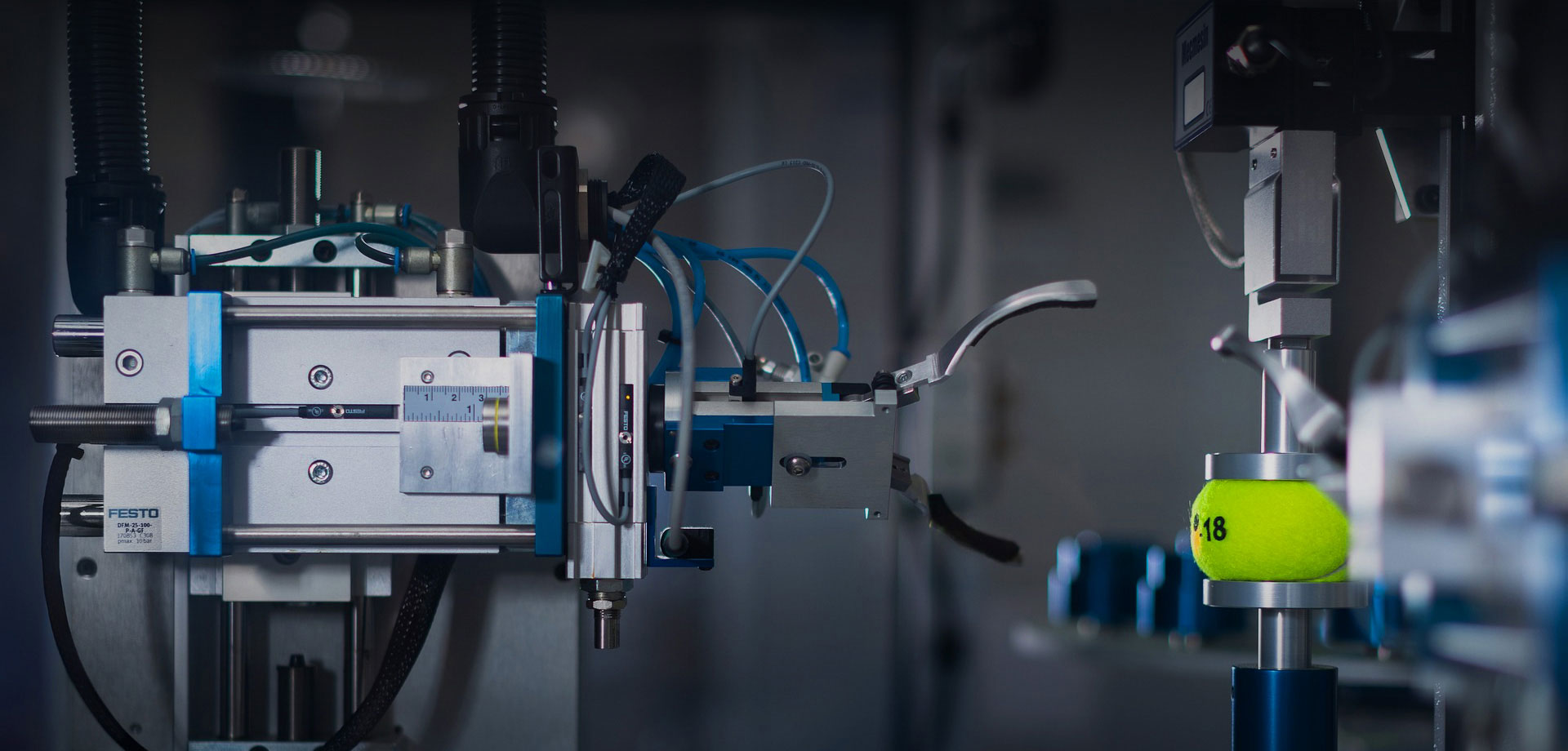

The new generation of intelligent tensile testing machines has integrated AI defect recognition technology, which can analyze the fracture morphology of samples in real-time during testing (such as distinguishing cleavage fracture from ductile fracture). This technology has been applied in the testing of Tesla battery separators.

V. Selection Suggestions

Users are advised to select configurations based on material characteristics:

Soft Materials (e.g., gels): Equipped with a non-contact video extensometer

High-Strength Materials (e.g., titanium alloys): Requires a load frame with a capacity of over 200kN

Company Profile: Shenzhen Zhongtian Measurement & Control Technology Co., Ltd.

I. Corporate Positioning and Technical Strength

As a national high-tech enterprise, Shenzhen Zhongtian Measurement & Control Technology Co., Ltd. was established in 2019 with a registered capital of 6 million RMB. The company specializes in the research and manufacture of testing equipment and measurement and control instruments. It possesses a complete industrial chain capability covering technology development, manufacturing, and after-sales service. The company has passed ISO 9001 and other international management system certifications, demonstrating its technical leadership in the field of precision measurement.

II. Core Business and Innovative Achievements

Product System

The product system includes electronic universal testing machines, material testing systems, and other equipment, with independent intellectual property rights.

Technological Breakthroughs

The R&D team accounts for over 40% of the company, with 54 patent applications filed.

Customization Services

The company provides scenario-based testing solutions for aerospace, automobile manufacturing, and other fields.

III. Market Applications and Industry Contributions

The company's products have served:

Scientific Research Institutions: Material laboratories of universities such as Tsinghua University

Industrial Sectors: Quality inspection in the supply chains of leading enterprises such as Sinopec and BYD

Healthcare: Medical material testing in compliance with YY/T 0681 standards

IV. Development Vision

With the concept of "Precise Measurement, Intelligent Control for the Future," the company continuously drives innovation in material testing technology, aiming to become a benchmark enterprise in the global measurement and control field.