In the fields of materials science and engineering, testing the mechanical properties of materials is a critical step in ensuring product quality. The ZTTEST Electronic Universal Tensile Testing Machine, as a high-precision testing device, is widely used for evaluating the mechanical properties of metals, plastics, rubber, fibers, and other materials. It can accurately measure the stress and deformation of materials under different conditions such as tension, compression, and bending, providing reliable technical support for research, production, and quality control.

What is an Electronic Universal Tensile Testing Machine?

An Electronic Universal Tensile Testing Machine is a device commonly used to test the mechanical properties of materials. It can apply constant or varying loads in a controlled environment and precisely measure the deformation and fracture characteristics of materials under different loads. The term "universal" comes from its broad applicability—it can perform not only tensile tests but also compression, bending, and various other mechanical tests, making it suitable for a wide range of materials.

Key Functions of an Electronic Universal Tensile Testing Machine

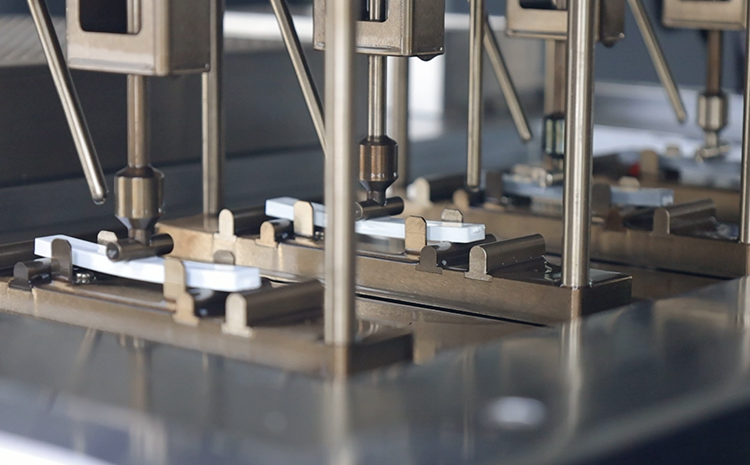

Tensile Testing

The Electronic Universal Tensile Testing Machine can accurately measure key indicators such as tensile strength, elongation, and yield strength. These metrics are essential for evaluating the tensile properties of metals, plastics, fibers, and other materials.

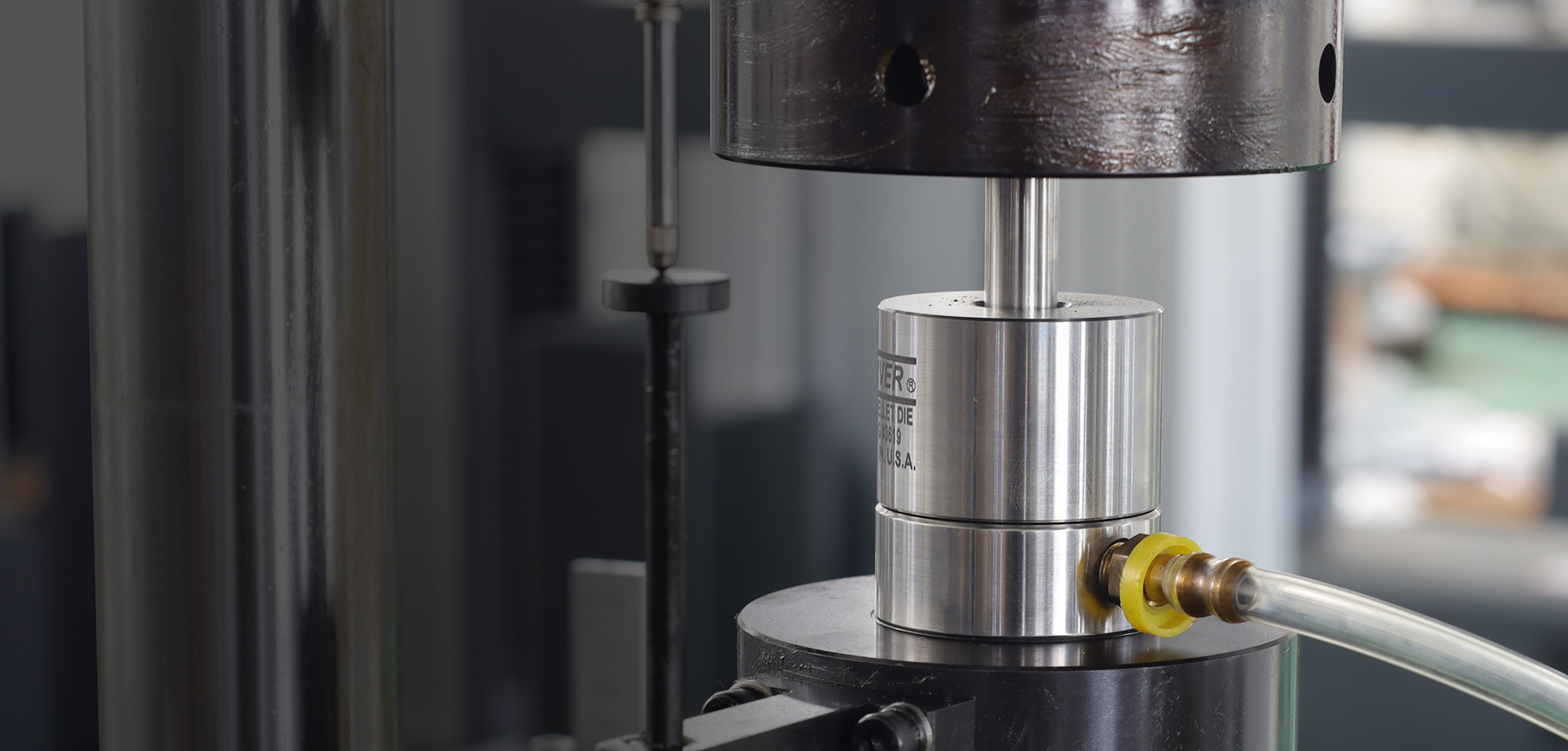

Compression Testing

This equipment can also perform compression tests to analyze the stress-strain behavior of materials under compressive forces, such as compressive strength and strain. Such data is vital for industries like construction and civil engineering.

Bend Testing

Bend testing is used to assess how materials behave under bending stress, commonly applied to evaluate the bending resistance of materials like steel bars and plastic sheets.

Fracture and Fatigue Testing

The Electronic Universal Tensile Testing Machine can also conduct fracture toughness and fatigue performance tests, evaluating how materials perform under repeated loads. This provides critical data for assessing long-term reliability.

Applications of Electronic Universal Tensile Testing Machines

Metal Processing and Material Production

In the metalworking industry, Electronic Universal Tensile Testing Machines are used to test the mechanical properties of metals such as steel and aluminum alloys. They help manufacturers ensure quality control during production and prevent the use of substandard materials.

Plastics and Rubber Industry

The elasticity, wear resistance, and tensile properties of plastics and rubber materials must be tested using an Electronic Universal Tensile Testing Machine. This is crucial for quality control in products like plastic pipes and rubber seals.

Textile Industry

Electronic Universal Tensile Testing Machines are widely used in the textile industry, particularly for testing the tensile strength and breaking elongation of fibers and fabrics, providing essential data for quality assessment.

Research and Development

In the development of new materials, Electronic Universal Tensile Testing Machines provide researchers with high-precision mechanical property data, helping them optimize material designs and develop higher-performance materials.

Quality Control and Certification

Across various industries, Electronic Universal Tensile Testing Machines are used for production line quality control, ensuring that each batch of products meets relevant standards. Test data from these machines is indispensable for international certification processes.

How to Choose the Right Electronic Universal Tensile Testing Machine?

Testing Range and Accuracy Requirements

When selecting an Electronic Universal Tensile Testing Machine, the first consideration should be the range of materials to be tested and the required accuracy. Different materials have varying strength and performance characteristics, so the machine's testing range and precision must meet the specific requirements of the materials being evaluated.

Automation and Smart Features

Modern Electronic Universal Tensile Testing Machines are typically equipped with intelligent control systems that automate the testing process and display data in real time. Choosing a device with data analysis and remote monitoring capabilities can improve testing efficiency and accuracy.

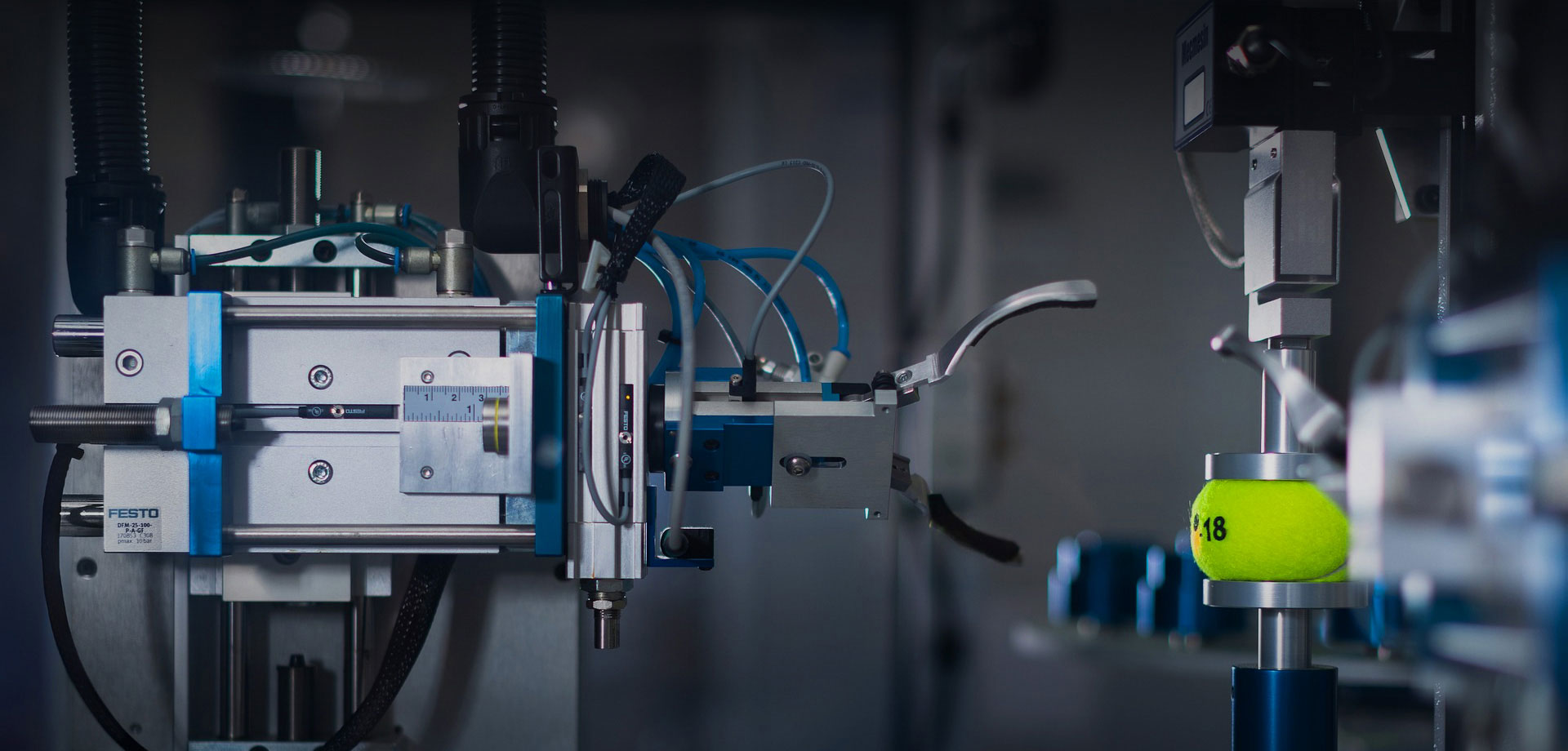

Diversity of Testing Fixtures

Depending on testing needs, Electronic Universal Tensile Testing Machines usually come with various fixtures, such as tensile grips, compression plates, and bending fixtures. Selecting the right fixture configuration enhances the accuracy of test results and the machine's versatility.

After-Sales Service and Maintenance

The long-term stability and accuracy of an Electronic Universal Tensile Testing Machine depend on regular maintenance and calibration. Therefore, choosing a supplier with comprehensive after-sales service and technical support is crucial to ensure timely maintenance and assistance during operation.

Conclusion

The Electronic Universal Tensile Testing Machine, as a multifunctional testing device, is an indispensable tool in modern materials science and engineering. It not only enables high-precision mechanical property testing for businesses and research institutions but also provides robust data support for quality control and new material development. By selecting the right Electronic Universal Tensile Testing Machine, companies can enhance production efficiency, reduce quality risks, and ensure the stability and reliability of their products.