1. Device Overview: What Does a Heat Deflection & Vicat Softening Point Tester Actually Measure?

The Heat Deflection & Vicat Softening Point Tester (commonly referred to as an HDT/VST tester) is a precision instrument designed to determine the thermal performance of non-metallic materials under load and elevated temperature. It’s essential for evaluating the heat resistance level of a material to determine its suitability for high-temperature environments.

The device integrates two core test functions:

Heat Deflection Temperature (HDT): The temperature at which a test specimen deforms under a specified stress.

Vicat Softening Point (VST): The temperature at which a flat-ended needle penetrates a test specimen to a depth of 1 mm under a specific load.

These measurements are critical for assessing the thermal stability of thermoplastics, thermosetting plastics, electrical insulation materials, and more.

2. Test Process Overview (Including HDT & VST)

HDT (Heat Deflection Temperature) Test Process

Prepare the specimen according to standard dimensions;

Mount it on a three-point bending fixture and apply a specific load (e.g., 0.45 MPa);

Heat at a constant rate (typically 120°C/h);

Record the temperature when the deformation reaches 0.25 mm—this is the HDT.

VST (Vicat Softening Temperature) Test Process

Fix the specimen horizontally in a holder;

Apply a flat-ended needle with a standard weight (e.g., 10N or 50N);

Heat the oil bath at a constant rate;

Record the temperature when the needle penetrates the specimen to 1 mm.

3.Testing Standards Reference

|

Standard Code

|

Title

|

Applicable Test Type

|

|

GB/T 1633

|

Method for Determining Vicat Softening Temperature

|

VST

|

|

GB/T 1634

|

Method for Determining Heat Deflection Temperature

|

HDT

|

|

ISO 306

|

Plastics — Vicat Softening Temperature

|

VST

|

|

ISO 75

|

Plastics — HDT Testing

|

HDT

|

Ensure that the equipment supports the above standards and features automatic temperature control and displacement measurement for accurate results.

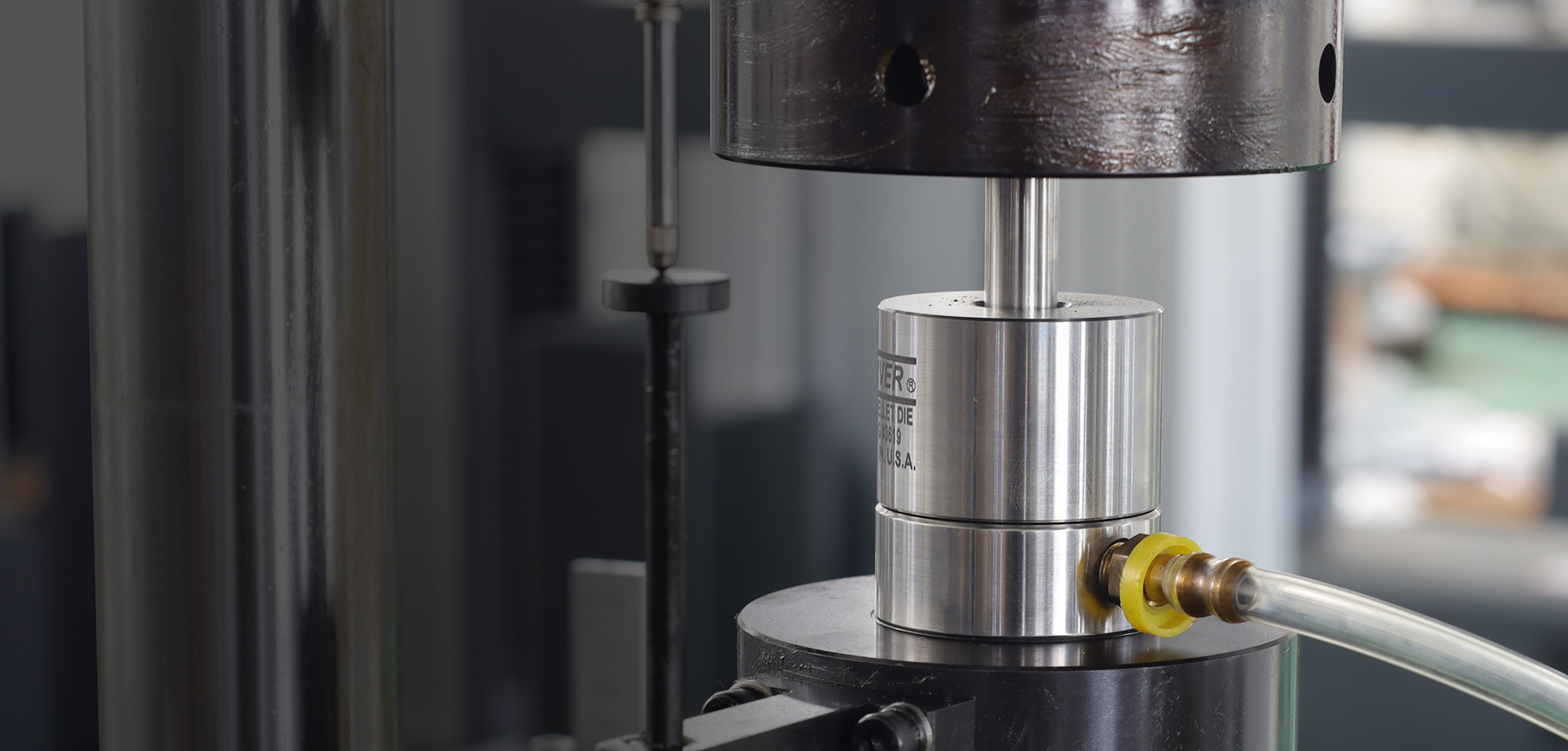

4.Key Components Breakdown (What to Look For When Buying)

|

Component

|

Function

|

Selection Tips

|

|

Heating Oil Bath

|

Provides stable and uniform temperature

|

Prefer PID closed-loop systems

|

|

Load Mechanism

|

Applies standardized load

|

Look for automatic weight switching options

|

|

Displacement Sensor

|

Measures deformation accurately (±0.01mm)

|

Optical sensors are highly recommended

|

|

Control System

|

Manages display, recording, and export

|

Should support USB data output and report printing

|

5. Application Fields and Typical Users

Material R&D Labs: For analyzing thermoplastic and thermoset performance

Quality Inspection Labs: For batch testing, compliance, and reporting

Educational Institutions: For hands-on training and demonstrations

Third-party Testing Agencies: For issuing certified test reports

6. Operation Essentials

Specimen Requirements

Vicat sample: (10 ± 0.2) mm length, (4 ± 0.1) mm thickness

HDT sample: (127 ± 1) mm length, (13 ± 0.2) mm width, (12.7 ± 0.2) mm thickness

Pre-Test Checklist

Calibrate load and temperature sensors

Check oil level and remove residues from oil bath

Set proper heating rate (commonly 50°C/h or 120°C/h)

Post-Test Data Processing

Auto-identify deformation depth or penetration depth

Graphical data visualization (optional)

Auto-generate PDF reports or print results directly

7. Common Issues & Troubleshooting

|

Issue

|

Possible Cause

|

Recommended Solution

|

|

Temperature fluctuation

|

Unstable oil bath control

|

Check sensor or clean heater

|

|

Irregular displacement

|

Faulty or misaligned sensor

|

Reinstall or replace sensor

|

|

Inaccurate results

|

Inadequate load or bad sample prep

|

Verify weight and sample size

|

|

Software lag

|

Overloaded system memory

|

Restart and clear software cache

|

8. Recommended Brands for HDT/VST Testers

Domestic Brands:

Jinan Jingji, Zttest, Beijing Beiguang, Huaheng

Pros: Cost-effective, fast after-sales, standards compliant

International Brands:

Zwick/Roell (Germany), Instron (USA)

Pros: High accuracy, robust software, ISO-certified

Conclusion: Focus on the Specs That Matter

When selecting a Heat Deflection & Vicat Softening Point Tester, it’s not just about cost. Focus on the specific materials you're testing, how frequently you use the machine, and which standards apply. A well-matched machine ensures accurate data, high efficiency, and long-term compliance for lab and industrial use.